Our Company

Our Company

Trusted infrastructure consulting expertise built on nearly four decades of nondestructive evaluation leadership. Our client-focused approach delivers trusted results.

Featured News

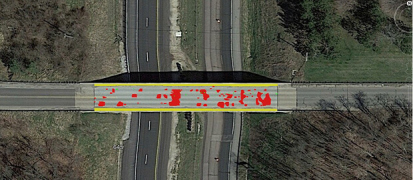

Services

Services

Comprehensive infrastructure assessments that minimize disruption while maximizing data quality. Our experienced teams deliver actionable reports and strategic recommendations that protect your assets.

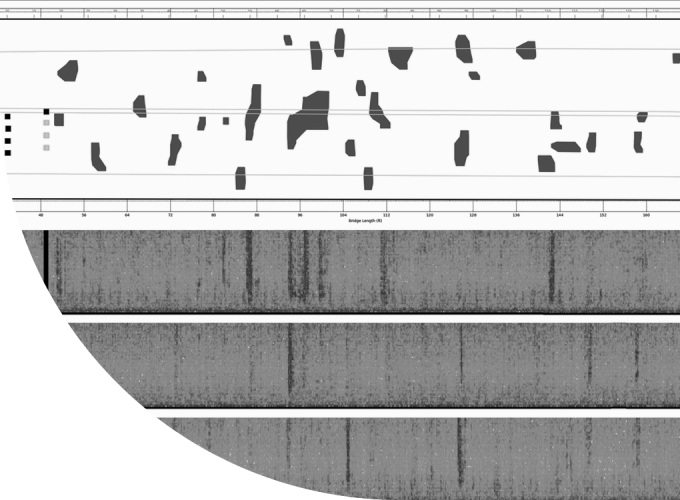

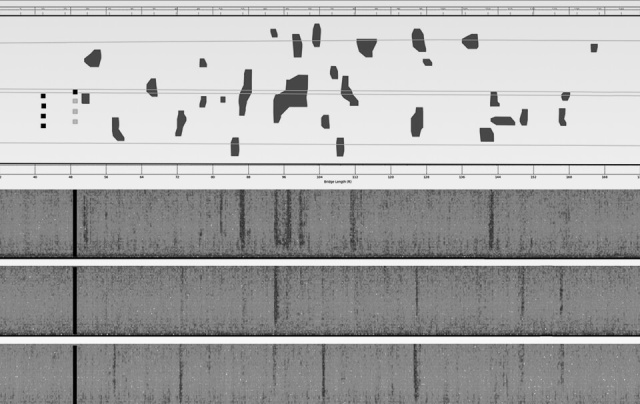

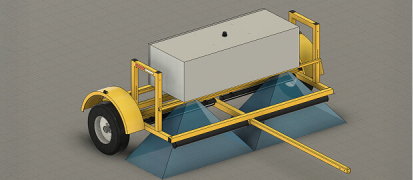

Technology

Technology

Advanced NDE technologies that reveal critical infrastructure conditions without costly shutdowns. Our proven methods deliver the precise data you need for confident maintenance decisions.